Tri-Mist 1400 Manual

Read this manual carefully before attempting to install or operate the Tri-Mist mist collector series. Retain these instructions for future use.

SAFETY RULES

Follow all electrical and safety codes as well as the National Electric Code (NEC), and the Occupational Safety and Health Act (OSHA). All electrical connections and wiring should be performed by qualified personnel only.

Make sure to consult with the machine tool manufacturer to confirm that the Tri-Mist is compatible with the machine tool and fire suppression equipment before installing the Tri-Mist.

The electrical power to the Tri-Mist must be wired into the emergency stop on the machine tool.

The Tri-Mist 1400 is made exclusively by Tri-Dim Filter Corporation. Should you have any technical questions

regarding the operation of the Tri-Mist 1400 please give us a call 800-544-0094 or 847-695-2600.

Safety:

Any individual operating the Tri-Mist 1400 is strongly recommended to read and understand the information supplied in the installation manual prior to using the mist collection system to avoid incorrect operation of the equipment or personal injury. While Tri-Dim Filter Inc. has made every effort to provide information regarding the safety for any and all individuals, this manual may not cover all possible contingencies regarding installation, operation and maintenance.

Warning Classifications:

DANGER – Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING – Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury. Examples of warning notices include hazardous

voltage, electrical current, temperature or other conditions that are associated with

the equipment or operation of the equipment.

CAUTION – Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Safety Precautions:

WARNING – Cutting oil in the machining process should not be used unless a fire

suppression system has been installed on the machine tool by a certified fire

prevention company.

WARNING – This Mist Collector is not explosion proof, do not use in explosive

atmospheres.

WARNING – The following is a list of suggested safety precautions:

- Read and follow all instructions and safety warnings in this Tri-Mist manual prior to using this system.

- Read and follow all instructions and safety warning provided by the machine tool manufacturer for the safe operation of the machine tool.

- Make sure to consult with the machine tool manufacturer to confirm that the TriMist is compatible with the machine tool fire suppression equipment before installing the Tri-Mist system.

- The Tri-Mist System must be wired into the emergency stop switch on the machine tool.

SPECIFICATIONS

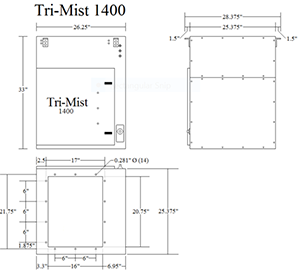

DIMENSIONS: 26” W x 26” D x 32” H

INLET OPENING: 16.7” x 21”

CABINET: 16 ga welded steel cabinet

WEIGHT: 210 Lbs installed

EFFICIENCY: 99.99 % +ASHREA 52.2, 95% DOP Efficiency

AIRFLOW: 50 – 1400 CFM

FILTRATION:

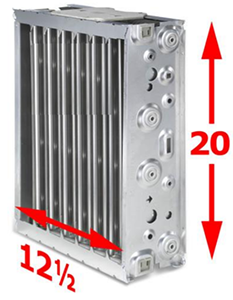

1st Stage: 4” thick Impinger

2nd Stage Dual ESP / 212-sq.ft surface area.

3rd Stage Dual ESP / 212-sq.ft surface area.

4th Stage Dual ESP / 212-sq.ft surface area.

5th Stage: 2” thick mist impinger

POWER SUPPLY: Three dual voltage solid-state self-regulating and UL approved.

IMPELLER : Backward Curved, vibration-free, direct drive rated at 1050 cfm.

ELECTRICAL: 115 Volts, 600 watts, 5.75 amps 230 Volts, 600 watts, 3 amps

POWER CORD: 10-foot power cord with standard plug.

NOTE: Tri-Mist units are not dual voltage, See schematic on the inside of the cell access door to determine the voltage of your Tri-Mist 1400.

INSPECTION

Inspect the Tri-Mist 1400 for any shipping damage that may have occurred. Any damage

should be noted and the carrier notified immediately.

TOOLS AND EQUIPMENT REQUIRED

The following list of tools that would be needed for a typical installation:

- Drill

- Reciprocating Saw

- Hand tools

PLANNING THE INSTALLATION

WARNING – This Mist Collector is not explosion proof, do not use in explosive atmospheres.

- The Tri-Mist 1400 should be located with consideration for access to the hinged door and the electrical compartment cover. The filter access door requires a minimum of 24” clearance in front of the door.

- The side access cover on the right hand side should be accessible, if possible.

- Mount the Tri-Mist 1400 as far from the chip conveyor opening as possible.

- The Tri-Mist 1400 is equipped with a 10ft power cord. Make sure the power source is within 10 ft of the Tri-Mist unit and that the power source voltage is compatible with the Tri-Mist 1400 that was ordered. The Tri-Mist 1400 is not dual voltage; check the schematic label on the inside of the filter access door.

INSTALLATION

CAUTION – The Tri-Mist Mist Control 1400 weighs 210 lbs, a crane or fork truck is recommended for the installation to avoid injury.

DIRECT MOUNT TO MACHINE ENCLOSURE

The Tri-Mist 1400 can be mounted directly to the enclosure on a machine tool. The collected mist droplets drain back into the machine tool through the air inlet of the TriMist 1400.

DIRECT MOUNT INSTRUCTIONS

CAUTION Sharp edges may be located on cut and drilled holes for this installation. Wear protective gloves during the installation.

Carefully remove all filters and ESP cells from the Tri-Mist 1400. Position the Tri-Mist

1400 on the machine tool in the desired position.

- Use the inlet opening and the mounting hole pattern on the bottom of the Tri-Mist 1400 as a template to mark the inlet and mounting holes to be cut into the enclosure. NOTE: The inlet opening in the machine tool does not need to be as large as the inlet of the Tri-Mist 1400. It is recommended that the inlet opening be a minimum of 64 square inches.

- Use a .281 Dia drill bit to drill the mounting holes for the ¼-20 bolts used to secure the Tri-Mist 1400 to the machine tool. There are 14 holes in the inlet flange of the Tri-Mist 1400. It is recommended that a minimum of four be used to secure the Tri-Mist 1400.

- Apply the silicone sealant provided between the enclosure and the Tri-Mist 1400. Bolt the Tri-Mist 1400 to the enclosure.

- Replace the filters and ESP cells. Make sure that the airflow arrows point up.

DUCTED INSTALLATION

When direct mounting the Tri-Mist 1400 isn’t possible or desired, the Tri-Mist 1400 can be installed with a plenum option bolted to the Tri-Mist 1400 inlet instead. This plenum has a drain and collars to connect to flex ducting.

Tri-Mist 1400 shown with optional Plenum and Machine Mount Stand

We recommend direct mounting when possible and limiting duct length when ducting is necessary.

INSTALLING THE PLENUM

- Install the supplied covers and collars to the plenum using the supplied silicone sealant and #8 nuts.

- Attach the plenum to the inlet opening using the supplied silicone sealant and ¼ -20 hardware provided. Note that the plenum can be rotated 180 degrees for the desired port location.

Tri-Mist 1400 shown with optional plenum.

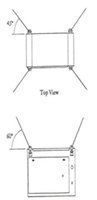

CEILING MOUNT

WARNING – For ceiling mounting, you must consider the weight of the Tri-Mist, Mist Control system, the ductwork and oil being collected. All ceiling support members must be sized to properly support the unit, ductwork and drain hardware.

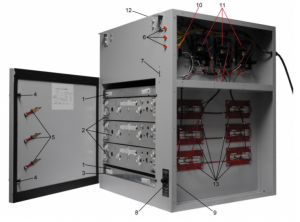

The ceiling hanging kit option provides 4 brackets and eyebolts. This allows the Tri-Mist 1400 to hang from the ceiling structure.

DRAIN INSTALLATION

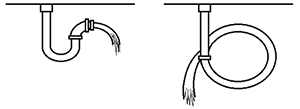

The Tri-Mist 1400 plenum has a ½ inch pipe thread (female) fitting for a drain. A P-trap is

required for the metal working fluids to drain properly.

Prime the P-trap with the metal working fluid to avoid air being drawn through the plenum. The

P-Trap can consist of a loop in a PVC hose or a hard pipe.

INSTALLING THE MACHINE MOUNT STAND

- Remove the six ¼” bolts on the back of the Tri-Mist 1400 and install the two L-brackets. Disregard this step if the unit was shipped with the brackets preinstalled.

- Carefully drill the required six holes in the machine tool to attach the L-brackets from the machine mount stand using 13/32” drill bit.

- Carefully lift the Tri-Mist 1400 onto the machine tool. Bolt the Tri-Mist 1400 to the machine tool using 3/8” nuts, bolts and lock washers.

INSTALL HEPA FILTER OPTION

- Install the four anchor brackets to the center of both sides of the unit. The ¼ – 20 bolts must be removed from the side panel and reused to install the brackets.

- Center the HEPA filter on top of exhaust grille with gasket side down.

- Install the HEPA retainer brackets by hooking one end to the filter frame and bolting the other end to the anchor brackets.

Tri-Mist 1400 shown with optional HEPA after filter.

ELECTRICAL INSTALLATION

DANGER ELECTRICAL SHOCK HAZARD

Tri-Mist 1400 system should only be installed by a qualified technician in accordance with the National Electrical Code (NEC), and the Occupational Safety and Health Act (OSHA). Improper electrical installation may damage equipment and can create a hazard causing possible injury or death.

The Tri-Mist 1400 System must be wired into the emergency stop switch on the machine

tool.

Cord Connected

The Tri-Mist 1400 is equipped with a 10-foot power cord. The 115 / 120 volt model includes a standard 15 amp rated plug. The 208-230 volt model is shipped with a 10-foot power cord with a 615-PA 2 pole plug. Please note that the Tri-Mist 1400 is not dual voltage.

START UP

- The Tri-Mist 1400 is equipped with a variable speed controller. Run the Tri-Mist 1400 on the lowest speed that will provide negative pressure in the machine tool enclosure.

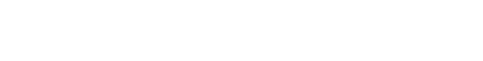

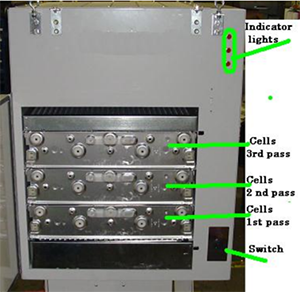

- The indicator lights should be on when the blower is running.

- The Tri-Mist 1400 is equipped with three test buttons to verify that the electronic filtration system is energized. Push each test button and listen for an arching sound. This indicates that the filtration system is energized.

MAINTENANCE

WARNING – Excessive accumulation on the filters (impingers and ESP cells) could result in fire damage

CAUTION – Be careful when handling the electronic cell, the metal edges may be sharp. Wear protective gloves when handling. Be careful not to damage the electronic cell, grip the cell on the frame so the thin collector plates are not damaged.

CAUTION – Tri-Mist 1400 has an interlock safety switch that disconnects electrical power to the filters when the filter access door is opened. To reduce the risk of electrical shock, do not perform any service other then filter cleaning unless power to the Tri-Mist 1400 and the machine tool has been safely disconnected and you are qualified to do so.

During the first month of operation, inspect the mist impingers and the electronic cells to help determine proper maintenance interval. When there is a buildup of coolant, it is time to clean the filters.

In general, to maintain peak performance, the Tri-Mist 1400 filters (impingers and ESP cells) should be cleaned a minimum of four times per year. This will insure maximum mist collection efficiency.

In some High Pressure Coolant applications the cells may need to be cleaned more frequently.

Parts Washer Method

The mist impingers and electronic cells can be cleaned with a parts washer. Make sure that the cleaning fluid used is aluminum safe and the maximum pressure does not exceed 65 psi. I would recommend an aqueous parts washer rather than a solvent based washer.

It is very important that the cell be rinsed very well to insure that all detergent is rinsed off. Check that the Ionizer wires are clean and smooth.

Manually Cleaning the Electronic Cells with a tub

Important: make sure that the detergent used is safe for aluminum and

that all of the detergent is rinsed off with hot water.

- Fill wash tub with hot water and detergent per manufacturer’s instructions.

- Immerse the cell in the cleaning solution for 5 minutes.

- Rinse cell with hot water making sure that no detergent residue remains.

- Check that the Ionizer wires are clean and smooth

- Replace cell back into Tri-Mist unit after allowing cell to drip dry for 20 minutes

Manually Cleaning the Electronic Cells with a Spray Bottle

Important: make sure that the detergent used is safe for aluminum and that all of the detergent is rinsed off with hot water.

- Spray detergent on the electronic cell until all surfaces on the cell are covered with detergent; allow the detergent to work on the cell for 7-10 minutes before rinsing.

- Rinse cell with hot water making sure that no detergent residue remains.

- Using a cloth, wipe each ionizer wire to remove any residual oil or water.

- On very dirty cells it may be necessary to repeat steps 1 through 3.

- Replace cell back into Tri-Mist unit after allowing cell to drip dry for 20 minutes.

Note: If water-soluble machining fluids are used, it would be best to spray a light coat of oil on to the electronic filter after washing. LPS or WD40 in a spray bottle are very effective. This light coating of oil makes the aluminum cell easier to clean for the next cleaning.

Electronic Cell Inspection

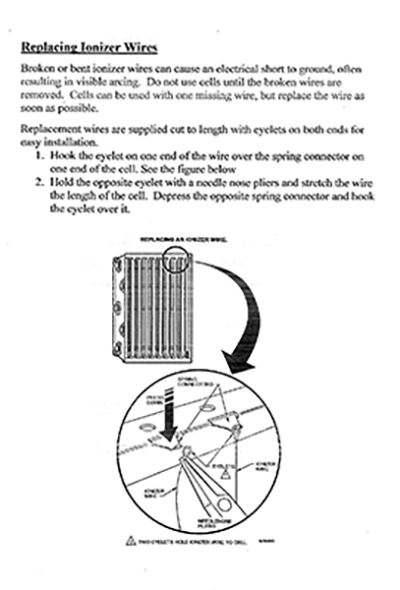

- Check that all 9 ionizer wires are in place and that there is no buildup of dirt on the wires. The ionizer wires should feel smooth.If they feel rough then there is a coating on dirt on the wires that needs to be removed either rewash the cells and wipe the wires with a cloth our use 600 grit emery paper and carefully go over the wires. If there are missing wires they should be replaced, see ionizer wire replacement on the following page.

- Check that the collector plates are secured to the support tubes. Loose collector plates cause arcing and can only be repaired at the factory.

- Check that there are no foreign objects wedged between the collector plates.

- If the cell appears to be clean and in good shape, then simply blow compressed air through the cells. Many times a foreign object is hard to see and the compressed air can dislodge it.

Manually Cleaning the Mist Impingers

Wash with a degreaser and rinse with hot water. Allow to dry or use compressed air to blow excess water off. The Mist impingers can be cleaned the same way you clean the electronic cells.

Cabinet

Using the same detergent, clean the inside and outside surfaces of the Tri-Mist once per year.

Trouble Shooting the Tri-Mist 1400

Turn the control switch on by rotating the control knob clockwise. The impeller (fan/motor) should come on as well as the Indicator Lights that confirm that the High Voltage Power supplies that energize the electronic cells are functioning properly. The Test Buttons (Red Plastic Buttons on the access door) should be pushed to confirm that the Electronic Cells are energized. Pushing the test buttons should create an arcing noise.

PROBLEM:

- Indicator Light is out – Please note that the Indicator Lights and the Impeller

(fan motor) operate independently. If the indicator light/lights are out, the

Impeller should still be moving air. If the indicator lights are out and the Impeller

is not moving air then the problem is one of the following:

a. No power to the Tri-Mist unit

b. Defective Control Switch

c. Defective Interlock Switch or poor alignment between the door tab

actuator and the interlock switch.

If the indicator lights are out and the Impeller is moving air then the problem is one of the

following:

a. Defective High Voltage Power Supply. There are three high voltage power

supplies, one for each set of cells. There are three Indicator Lights on the TriMist 1400 triple pass. The top Indicator Light is for the top two Electronic

Cells; likewise the middle Indicator Light is for the middle Electronic Cells

and the bottom indicator light is for the bottom Electronic Cells.

b. Dirty / shorted out Electronic Cells. If the top Indicator Light is out, then the

problem is with the top two Electronic Cells or the High Voltage Power

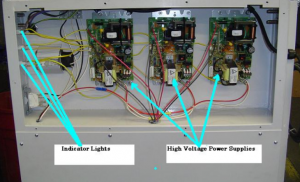

Supply that energizes the two cells.To determine if the problem is with the High Voltage Power Supply or the Electronic Cells, remove the Electronic Cells and turn the unit on. If the Indicator Light comes on then the High Voltage Power Supply is fine and the problem is with one or both of the Electronic Cells. You can slide one cell in at a time to determine which cell is defective. Once you have determined which cell is creating the problem, and then proceed to Electronic Cell inspection below. If the Indicator Light does not come on with the cells removed from the unit then the problem is with the High Voltage Power Supply. The power supply will need to be replaced. There are (4) hex nuts to remove and (6) wires. All wire connections are quick clips that slide off of the wire terminals.

- No Airflow – If the control switch has been turned on and there is no airflow and the indicator lights are illuminated, then the Impeller is defective and will need to be replaced. It is a good idea to replace the capacitor with the Impeller.

- Nuisance Arcing Noise – Many times Nuisance Arcing also causes the Indicator Light to flicker. This problem is usually caused by a problem with the Electronic Cell. The first step is to remove the cell or cells to make sure that the arcing noise stops to isolate the problem cell. See Electronic Cell inspection

- Passing mist / smoke – Check that the Indicator Lights are illuminated and that the Test Buttons produce an arcing noise, if so, then the problem is with the Electronic Cells. See Electronic Cell inspection

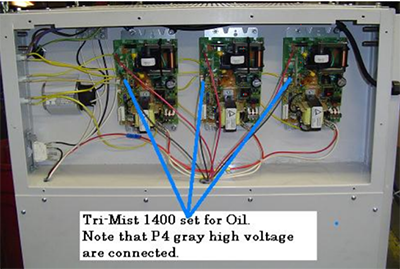

Tri-Mist 1400 – Metal Working Fluid Connections

The Tri-Mist 1400 can operate with all metal working fluids. If the coolant is water based, we then need to remove the P4 wire connections on all three High Voltage Power Supplies.

DANGER – ELECTRICAL SHOCK HAZARD:

Make sure power is disconnected before removing the access cover.